GKS-LC3005G

Full Cover Laser High Speed Cladding Machine

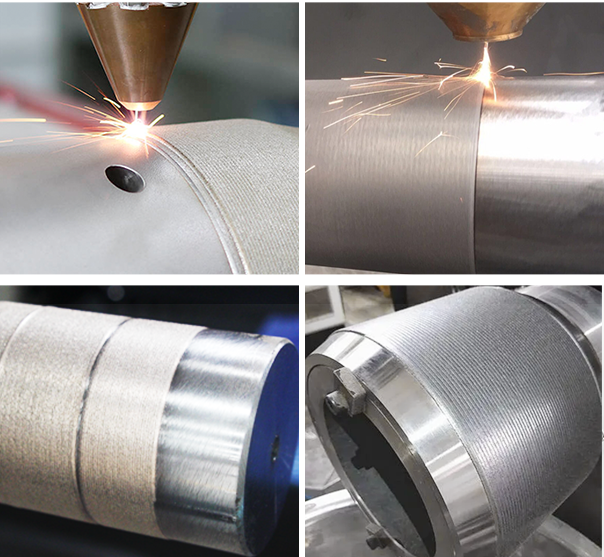

The machine bed adopts a thick steel plate welded structure, with high overall structural strength and processing accuracy, effectively ensuring accuracy and stability during operation.

The powder collection box is used to collect metal powder during the processing process, which can be recycled and reused in the later stage.

The vertical beams are welded with steel plates, which have high strength and good stability. It can stabilize the operation of the cantilever.

The powder feeder is a single-cylinder air-borne powder feeder that transports powder with carrier gas. This powder feeder is mainly suitable for laser cladding, 3D printing and other applications. It is mainly used to transport powdery materials. The powder particle size is about 20-400μm in diameter. , the powder feeding amount error is less than 2%, and the repeated powder feeding amount error is less than 1%. Only inert gases such as argon, nitrogen, and helium can be used as powder carrier gases. Oxygen, hydrogen, and other flammable gases cannot be used. Change the feeding rate and particle size by replacing different powder feeding trays. The design is reasonable and the sealing performance is good, so it can use higher carrier gas pressure and is suitable for long-distance powder feeding.

| Machine model | GKS-LC3005G |

| Laser power | 6000W-12000W |

| Auxiliary support | Supportable workpieces range Φ100-Φ550mm |

| Maximum equipment load | 3 tons(Load capacity can be customized) |

| Workpieces rotation diameter | ≤600mm(customizable) |

| X-axis stroke | 500mm |

| Y-axis stroke | 3000mm |

| Z-axis stroke | 450mm |

| Length of processing Workpiece | ≤3m(customizable) |

| Equipment system | PLC(Omron) |

| Cladding head | G.WEIKE Customized Cladding Head |