The whole machine is equipped with dual bus motors. The whole machine has a dry running speed of 120m/min and an acceleration of 1.5G, achieving leading dynamic performance.

Acceleration

Dry running speed

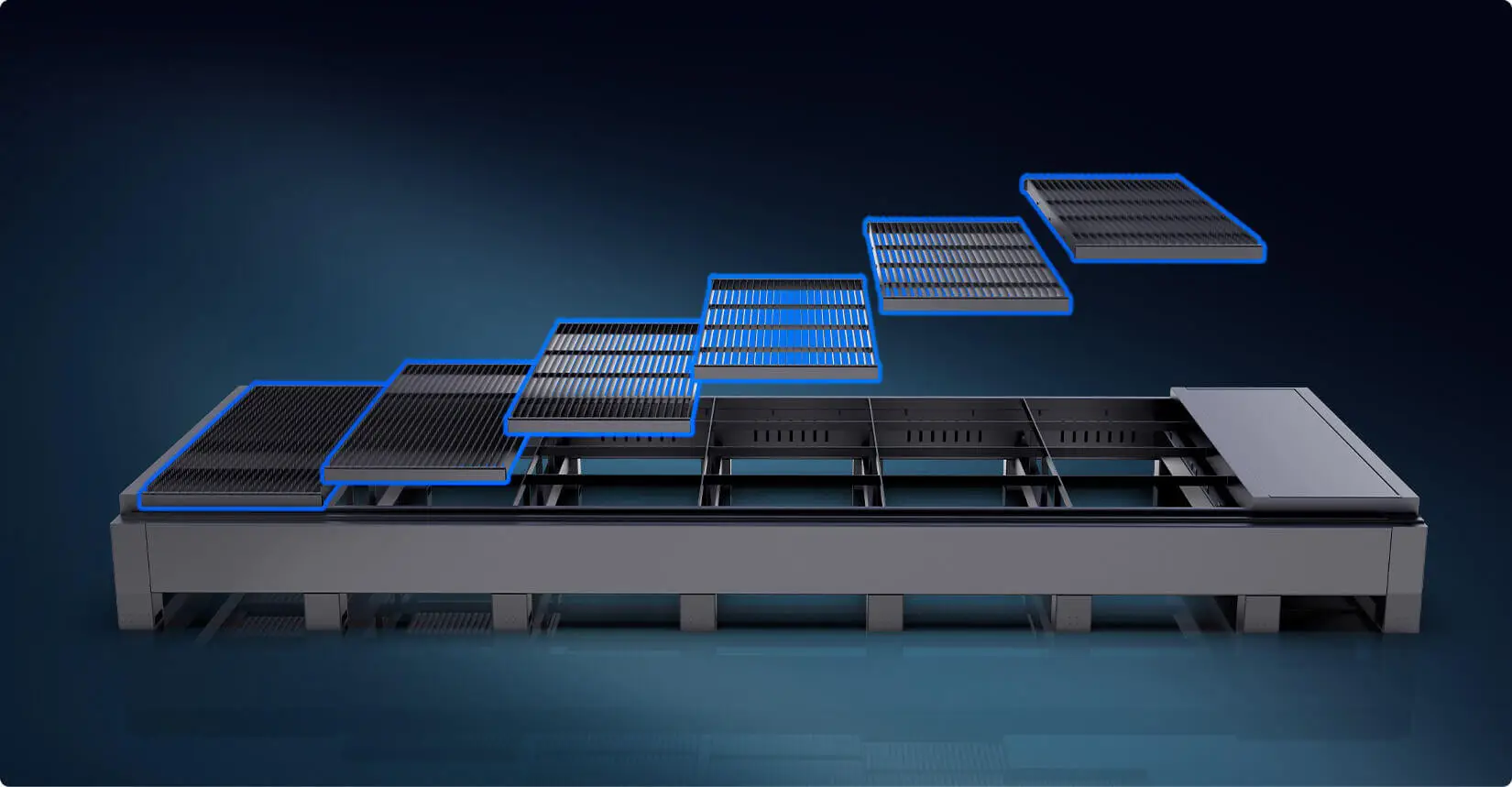

Ease of transportation while reducing later maintenance costs.

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Light weight, high strength,

Increased intensity

Reduce weight

The outlet air pressure can accurately reach the set value.

Automatically complete nozzle replacement, help automatic processing.

Z-axis real-time automatic adjustment, reduce cutting jitter abnormal.

Flexible cutting to avoid collisions with protruding parts, reducing collision risks.

|

|

|

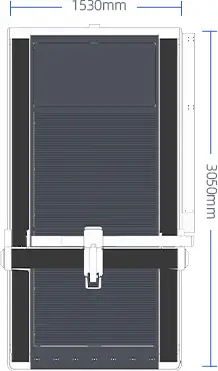

| LF3015LN LN Series |

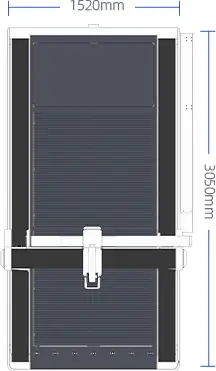

LF3015LN IILN Series |

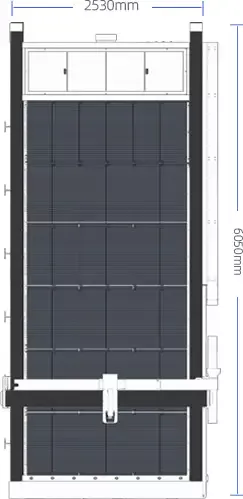

LF6025LN IILN Series |

| 3050*1530mmWorking area | 3050*1520mmWorking area | 6050mm*2530mmWorking area |

| (Optional)3000W/2000W/1500W/1000WLaser power | (Optional)3000W/2000W/1500W/1000WLaser power | (Optional)12000W/3000W/2000W/1500W/1000WLaser power |

| 4520*3030*1950mmDimensions | 4480*2770*1950mmDimensions | 7800*4100*2000mmDimensions |

| ±0.05mmX/y axis positioning accuracy | ±0.05mmX/y axis positioning accuracy | ±0.05mmX/y axis positioning accuracy |

| ±0.03mmX/y axis repeat positioning accuracy | ±0.03mmX/y axis repeat positioning accuracy | ±0.03mmX/y axis repeat positioning accuracy |

| 80m/minMaximum speed | 80m/minMaximum speed | 100m/minMaximum speed |

| 1GMax. acceleration | 1GMax. acceleration | 1.5GMax. acceleration |