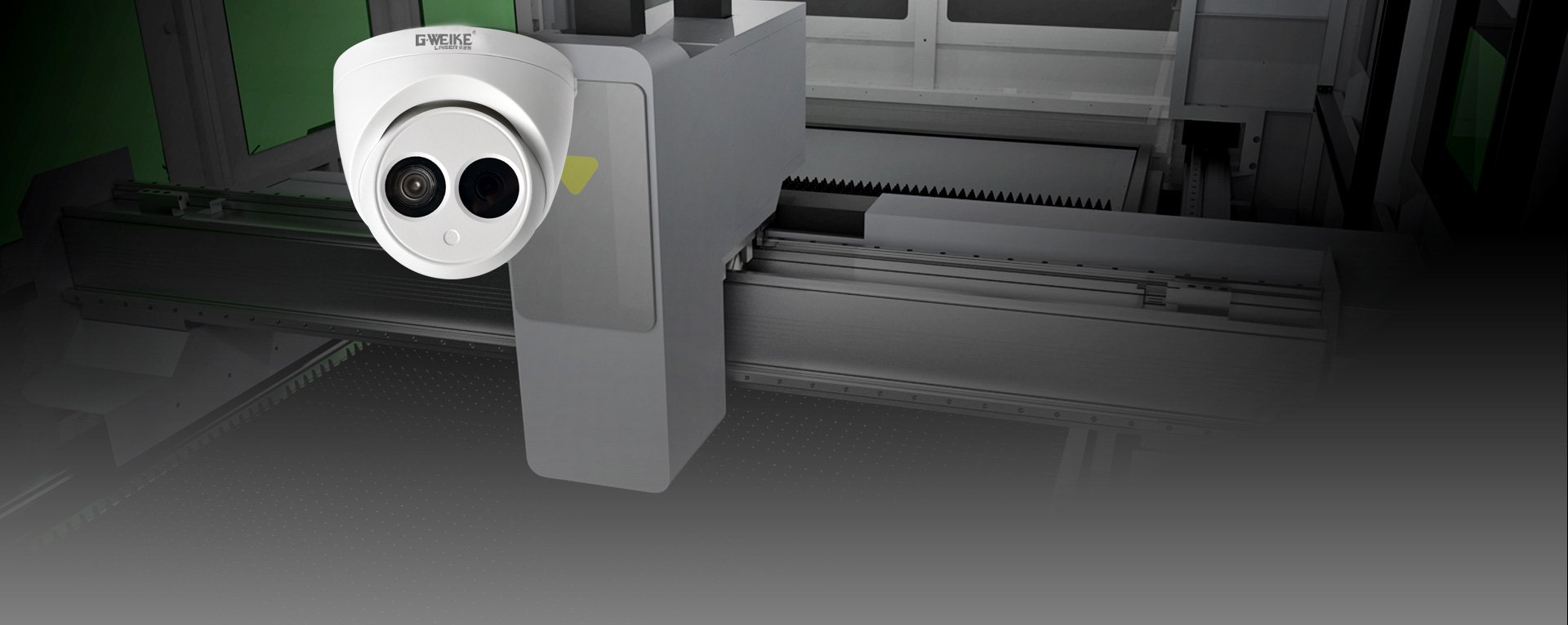

Real-time observe the machine running through the panel

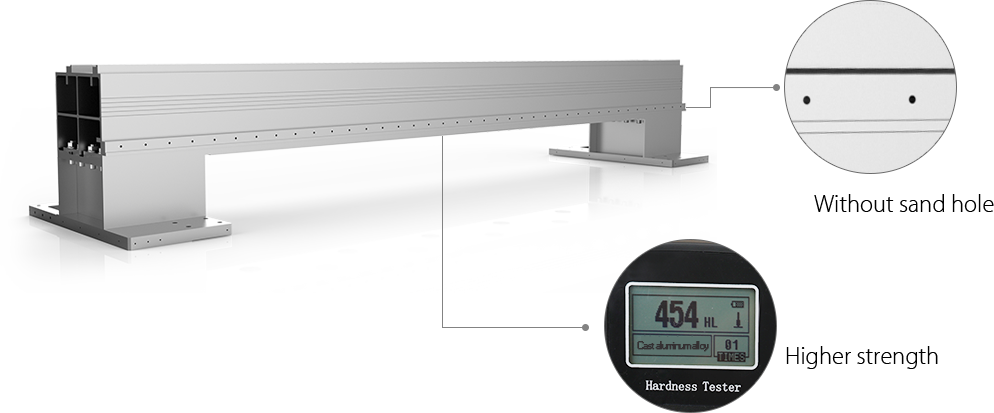

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

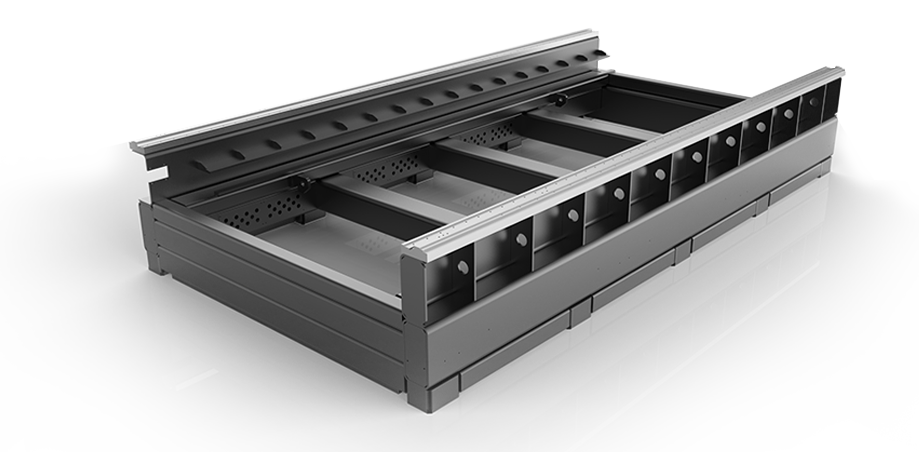

The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a number of rectangular tubes. Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the bed, it also increases the resistance and stability of the guide rail so as to effectively avoid the deformation of the bed.

German Tech Quality

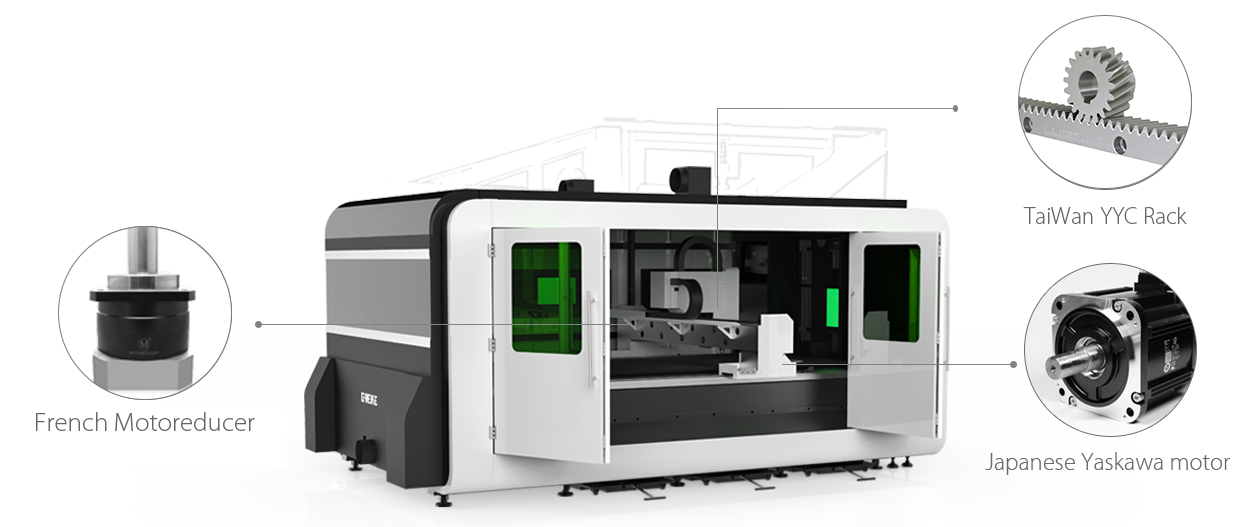

German Tech Quality G·WEIKE fiber laser cutting machine is equipped with Taiwan YYC rack, Japanese Yaskawa motor and French Motoreducer. The repeat positioning accuracy of the machine tool can be 0.02mm and the cutting acceleration is 1G. The working life is up to 10 years.

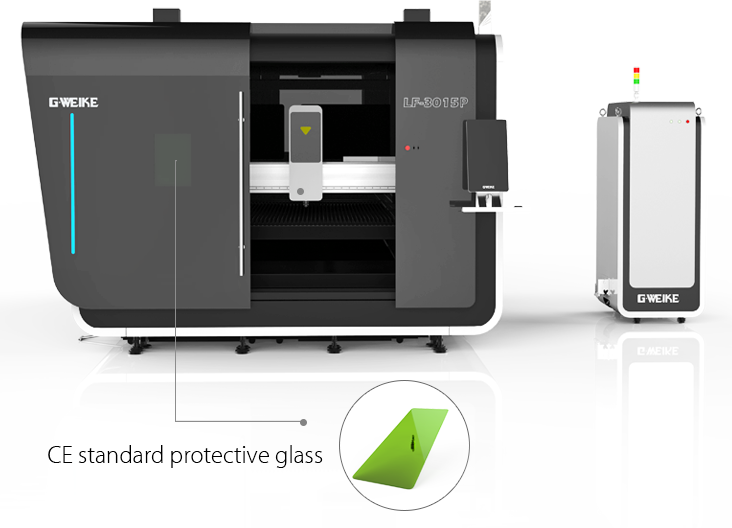

| Machine model | LF3015P |

| Laser power | 1000W 2000W 3000W 4000W 6000W 8000W(Optional) |

| Dimensions | 5425*3150*2530mm |

| Working area | 3000mm x 1500mm |

| Repeat positioning accuracy | ±0.02mm |

| Maximum speed | 120m/min |

| Max. acceleration | 1G |

| Voltage and frequency | 380V 50Hz/60HZ |

LF3015P fiber laser cutting machine can carry up to 8000W laser power, so cutting some thick plate, it is a very good choice. For example, agricultural machinery, textile machinery, food machinery and construction machinery and other large machinery and equipment manufacturing, usually use high power fiber laser cutting machine for processing.

Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, aluminum-plating zinc plate, copper, and other metals.