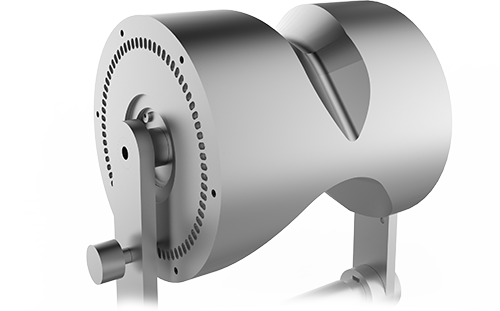

3015CR fiber laser cutting machine can not only cut metal plates, but also metal pipes. It has many uses and can save the space of more than 50%, which effectively improve productivity.

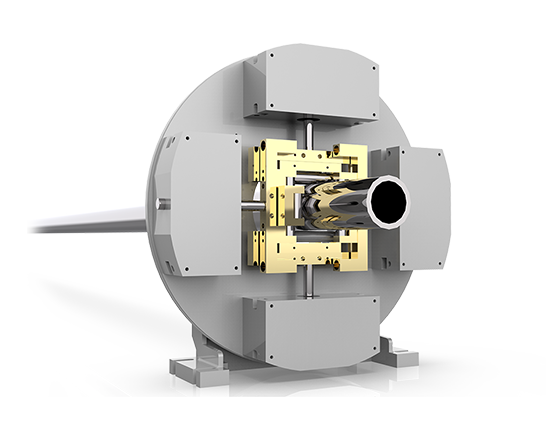

It adopts an electric clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-200mm.

It employs intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

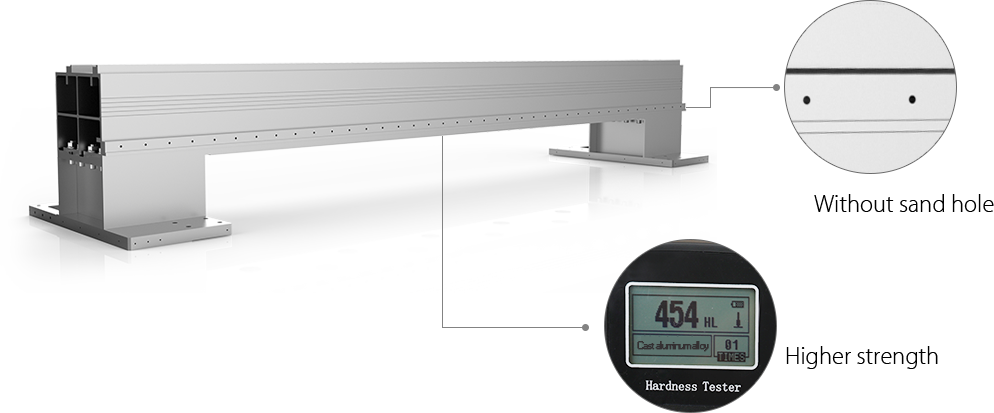

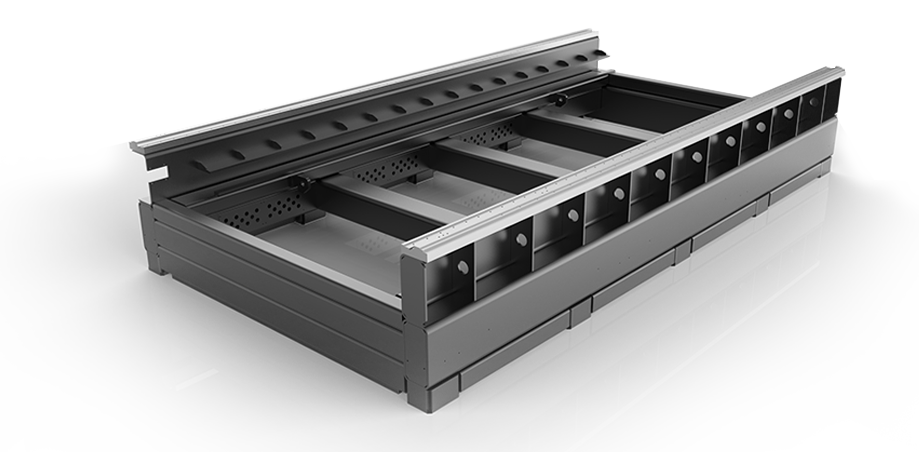

The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a number of rectangular tubes. Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the bed, it also increases the resistance and stability of the guide rail so as to effectively avoid the deformation of the bed.

German Tech Quality

German Tech QualityG·WEIKE fiber laser cutting machine is equipped with Taiwan YYC rack, Japanese Yaskawa motor and French Motoreducer. The repeat positioning accuracy of the machine tool can be 0.02mm and the cutting acceleration is 1G. The working life is up to 10 years.

| Machine model | LF3015CR |

| Laser power | 1000W 2000W 3000W 4000W 6000W 8000W(Optional) |

| Dimensions | 4760*4048*1950mm |

| Working area | 3000*1500mm |

| Repeat positioning accuracy | ±0.02mm |

| Maximum speed | 80m/min |

| Maximum acceleration | 1G |

| Specified voltage and frequency | 380V/50Hz/60Hz/60A |

Since sheet and pipe integrated design, Industry adaptability of LF3015CR

has been greatly enhanced, including petroleum and pipe material, fitness

equipment and other pipe material mainly mechanical processing, automotive

manufacturing, machine cabinet and other board materials mainly mechanical

processing, etc.

Specially used for cutting 0.5-5mm carbon steel sheets

(pipes), 0.5-2.5mm stainless steel sheets, galvanized

steel(pipes), electrolytic zinc-coated steel sheet(pipes),

silicon steel(pipes) and other kinds of thin metal sheets

and pipes. Range of pipe diameters: 20-220mm.