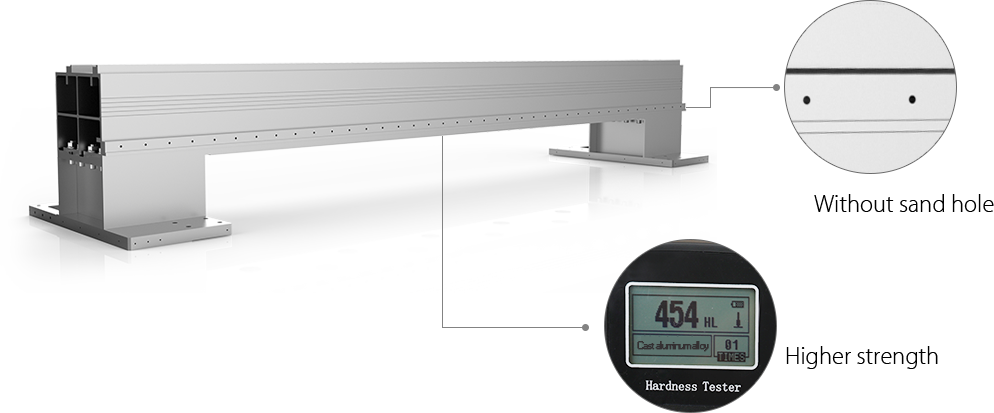

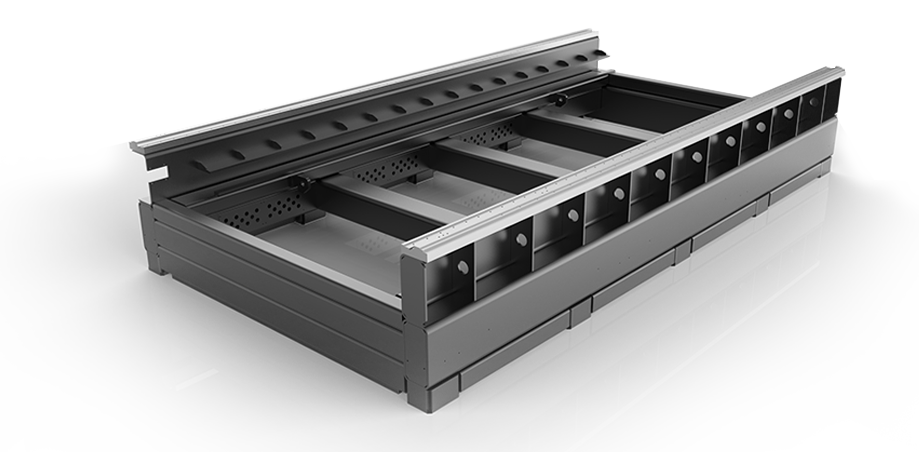

Rectangular-tube lattice with internal ribs (10 mm wall, ~4.5 t). The heavy, honeycomb-like frame boosts rail stability and thermal flatness for long sheet runs, helping the bed hold accuracy for ~20 years without warp.

German Tech Quality

German Tech QualityPrecision drive: ATLANTA rack + YASKAWA servos + NEUGART reducer. Delivers ±0.02 mm repeatability and up to 1.5 G for small, intricate sheet parts—built for a decade-long duty cycle.

| Machine model | LF3015C |

| Laser power | 1000 W 2000 W 3000 W 4000 W 6000 W 8000 W (Optional) |

| Dimensions | 4600 × 2450 × 1700 mm |

| Working area | 3000 mm × 1500 mm |

| Repeat positioning accuracy | ±0.02 mm |

| Maximum speed | 120 m/min |

| Power consumption | < 10 kW |

| Voltage and frequency | 380 V / 50 Hz / 60 Hz / 60 A |

LF3015C fiber laser cutting machine as one classic model, widely used in life,

such as processing of stainless steel kitchenware, storage cabinet and other cabinets,

is closely related to people's daily life.

Core sheet work—kitchen & appliance panels, storage/cabinet frames, enclosures and brackets in CS/SS/AL, galvanized and alloy plates—where clean kerfs and steady repeatability matter.

Thickness depends on laser power, nozzle/gas, and process. Typical ranges: 1–2 kW handles carbon steel ≤8 mm, stainless ≤5 mm, aluminum ≤4 mm; 3–4 kW up to ~12 mm carbon steel, ~8 mm stainless, ~6 mm aluminum; 6–8 kW up to ~20 mm carbon steel, ~12 mm stainless, ~10 mm aluminum (with proper gas and nozzle setup).

Match power to your most common material and thickness. For thin to mid-thin sheets (≤6–8 mm) and best cost-performance, 1–2 kW is typical. If mid-thick sheets (8–12 mm) are frequent, consider 3–4 kW. For regular 16–20 mm carbon steel or comparable stainless thicknesses, 6–8 kW offers the efficiency headroom. Click here for more information on Laser Cutting Machines.

LF3015C is listed at ±0.02 mm repeatability, max speed around 120 m/min, and up to ~1.5G acceleration on a single platform (subject to site conditions and process setup).

Standard work area is 3000 × 1500 mm. Overall dimensions are about 4600 × 2450 × 1700 mm, convenient for single-table layouts and shop flow planning.

Rated power is 380V / 50–60Hz / 60A (industrial three-phase). Typical system consumption is < 10 kW (varies with laser power and options). We recommend a dedicated circuit and appropriately sized breaker.

Oxygen is common for carbon steel (fast but oxide edge). Nitrogen is typical for stainless/aluminum (bright, oxide-free edge). For thin gauges where edge color is acceptable, shop air can be considered. See our Assist Gas technical article.

It supports a −10 to +10 mm focus range with 0.01 mm steps, enabling one-click recipe switching across thicknesses. Water-cooled collimating/focusing stacks help reduce thermal drift and extend head life—while minimizing manual adjustments.

Carbon steel, stainless steel, aluminum/aluminum alloys, galvanized sheets, and common engineering alloys for sheet cutting. For specific grades and thicknesses, we recommend test cuts with our applications team.

Per shift/day: clean protection lens and nozzle; check gas and coolant filtration. Weekly: verify rail lubrication and rack & pinion condition. Monthly: check optics and parameters; maintain coolant quality/temperature; service fume extraction/filtration.