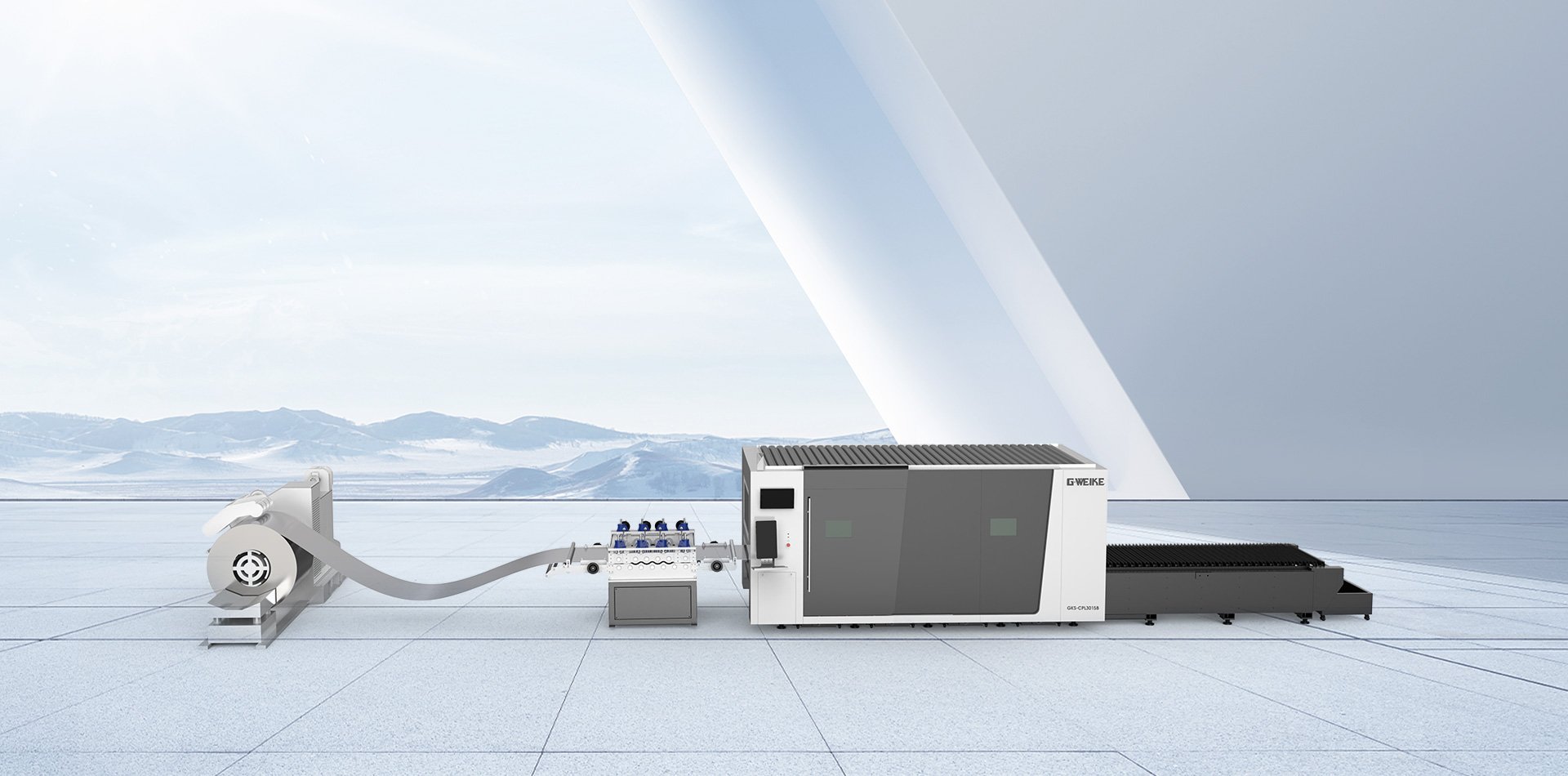

CPL3015B

GWK Special Fiber Laser Cutter for Industry Use

Video Show

Through intelligent control, different products can be produced by importing processing drawings, meeting the batch production needs of different shapes and variable workpieces.

Unwinding, leveling, cutting, intelligent and automated material handling, continuous operation, reducing manual dependency.

The coil material conveying equipment continuously transports materials, with synchronous feeding and unloading, seamless cutting connections, further enhancing efficiency.

Automotive manufacturing, office furniture, electrical industry, chassis cabinets, elevator manufacturing, kitchenware,

decorative curtain walls, machinery manufacturing, mold industry, rail transportation, medical equipment, office furniture.

| Machine model | GKS-CPL3015B | GKS-CPLS6015B |

|---|---|---|

| Laser power | 1000W-6000W | 1000W-6000W |

| Working area | 3000*1500mm | 6000*1500mm |

| Coiled material inner diameter | Φ508mm - Φ610mm | Φ508mm - Φ610mm |

| Coiled material width | 500-1500mm | 500-1500mm |

| Coiled material thickness | 0.8~3mm(carbon steel) 0.8~2mm(stainless steel) | 0.8~3mm(carbon steel) 0.8~2mm(stainless steel) |

| Maximum outer diameter of coiled material | Φ1500mm | Φ1500mm |

| Minimum outer diameter of coiled material | Φ800mm | Φ800mm |

| Maximum material weight | 10 T | 10 T |

| Feeding speed | 0-20m/min | 0-20m/min |

| X/Y axis positioning accuracy |

±0.05mm/m | ±0.05mm/m |

| X/Y axis repeat positioning accuracy |

±0.03mm | ±0.03mm |

| X/Y axis maximum acceleration |

1.0G | 1.0G |

| X/Y axis maximum moving speed |

120m/min | 120m/min |

| Dimension | 15500*6000*2550m | 16000*4000*2100mm |