Cantilever Shaped Steel

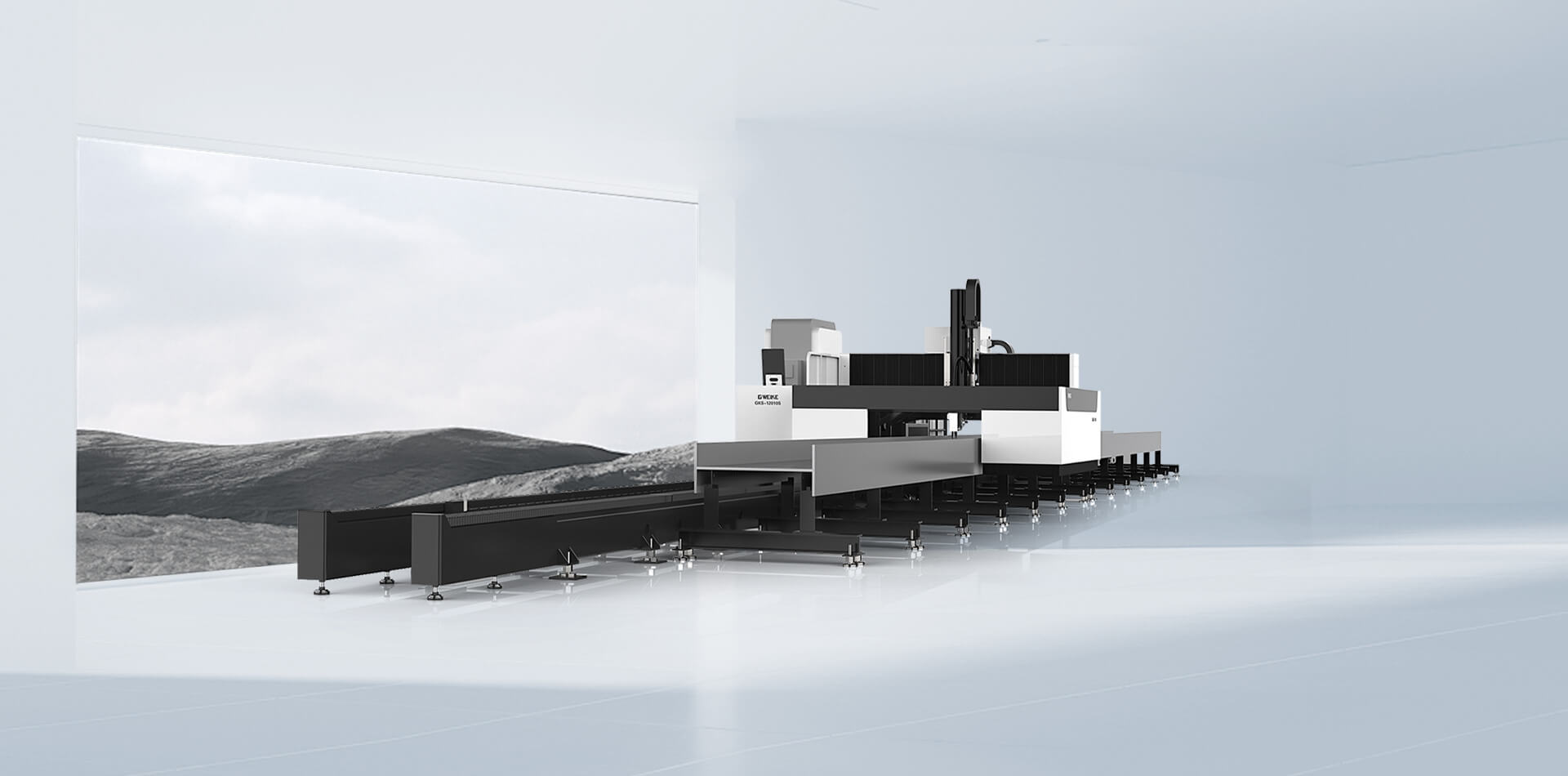

Cantilever Shaped Steel Laser Cutting Machine

Video Show

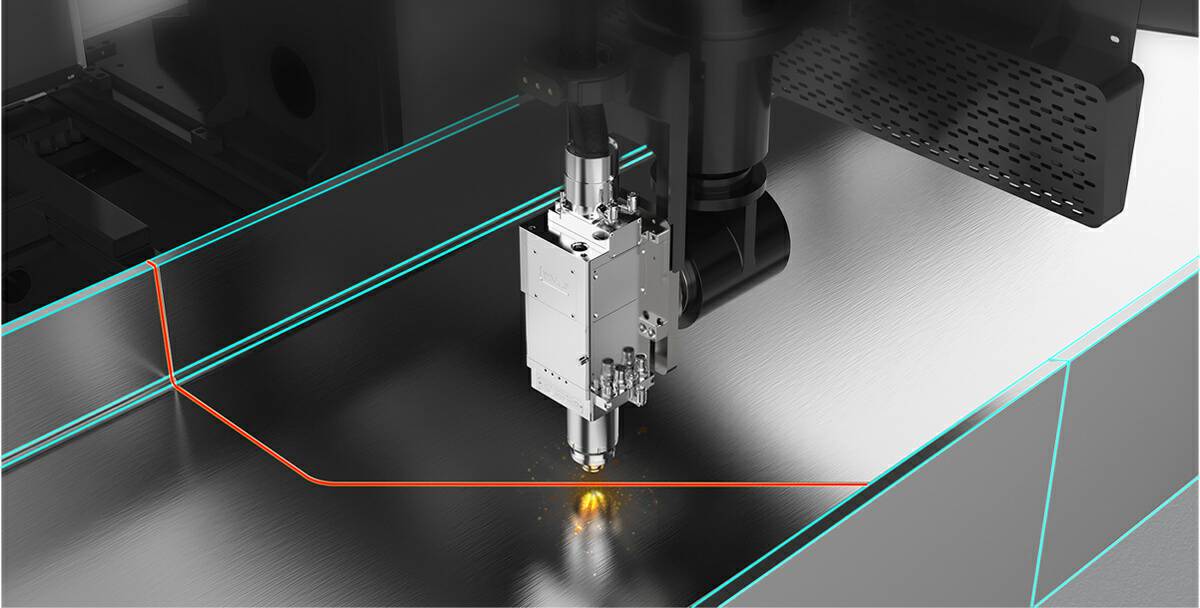

Cutting, perforating, beveling, locking, marking, and lining up all done in one machine.

Modular design,

Double workstation up to 25.5 meters long,

Meeting the demand for large-scale processing.

Supports TEKLA steel structure 3D modeling data file cutting without the need for separate drawings, intelligent and fast nesting.

Supports contour detection, data transmitted in real-time to the processing system, real-time compensation for steel deformation areas, minimal thermal deformation, smooth cross-sections.

Easier loading & unloading to lower labor costs

Intelligently adjust tool retraction pressure for smooth tool retraction.

Rapid slag removal after perforation, improving quality and efficiency.

Steel structure construction, engineering machinery, metal processing, bridge tunnels, vehicle frames, port machinery.

| Machine model | GKS-12010S |

|---|---|

| Laser power | 12000W(Optional 20000W/30000W) |

| Y-axis/Z-axis travel | 2000mm / 26000mm / 1050mm |

| Maximum acceleration | 0.3G |

| X/Y axis positioning accuracy | ±0.25mm/m |

| X/Y axis repeated positioning accuracy | ±0.05mm |

| Power specifications | 380V/50Hz |

| Layout size | 34500*4700*3500mm |