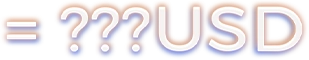

Enter Email to unlock the SUPER EARLY BIRD PRICE

(Save Up To $3000)

Become a member of our VIP group on Facebook

Complete both steps for a chance to win a free machine!

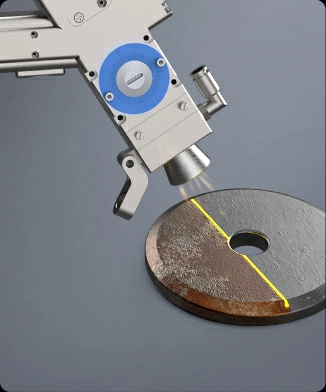

CNC Gantry Cutting

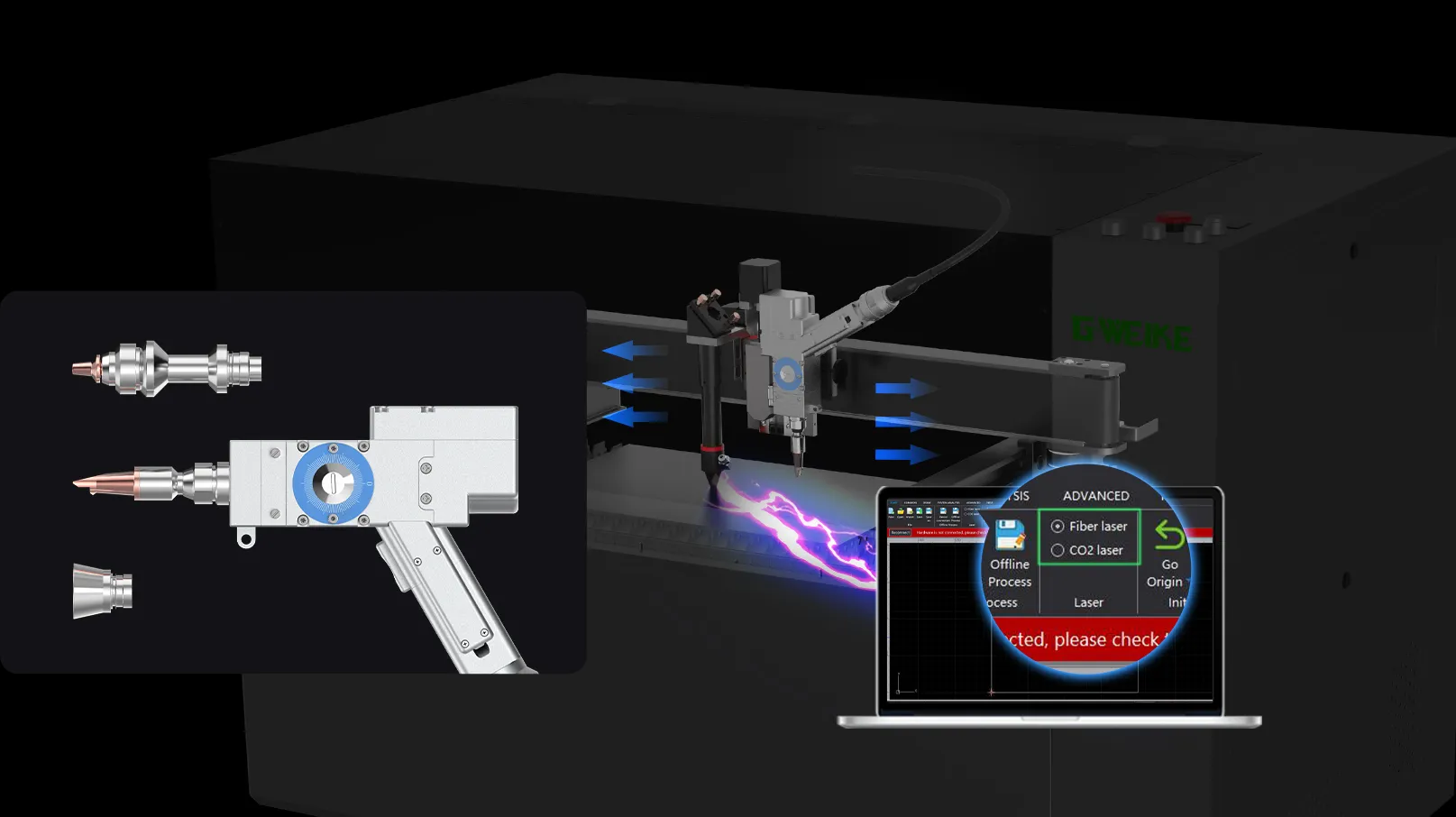

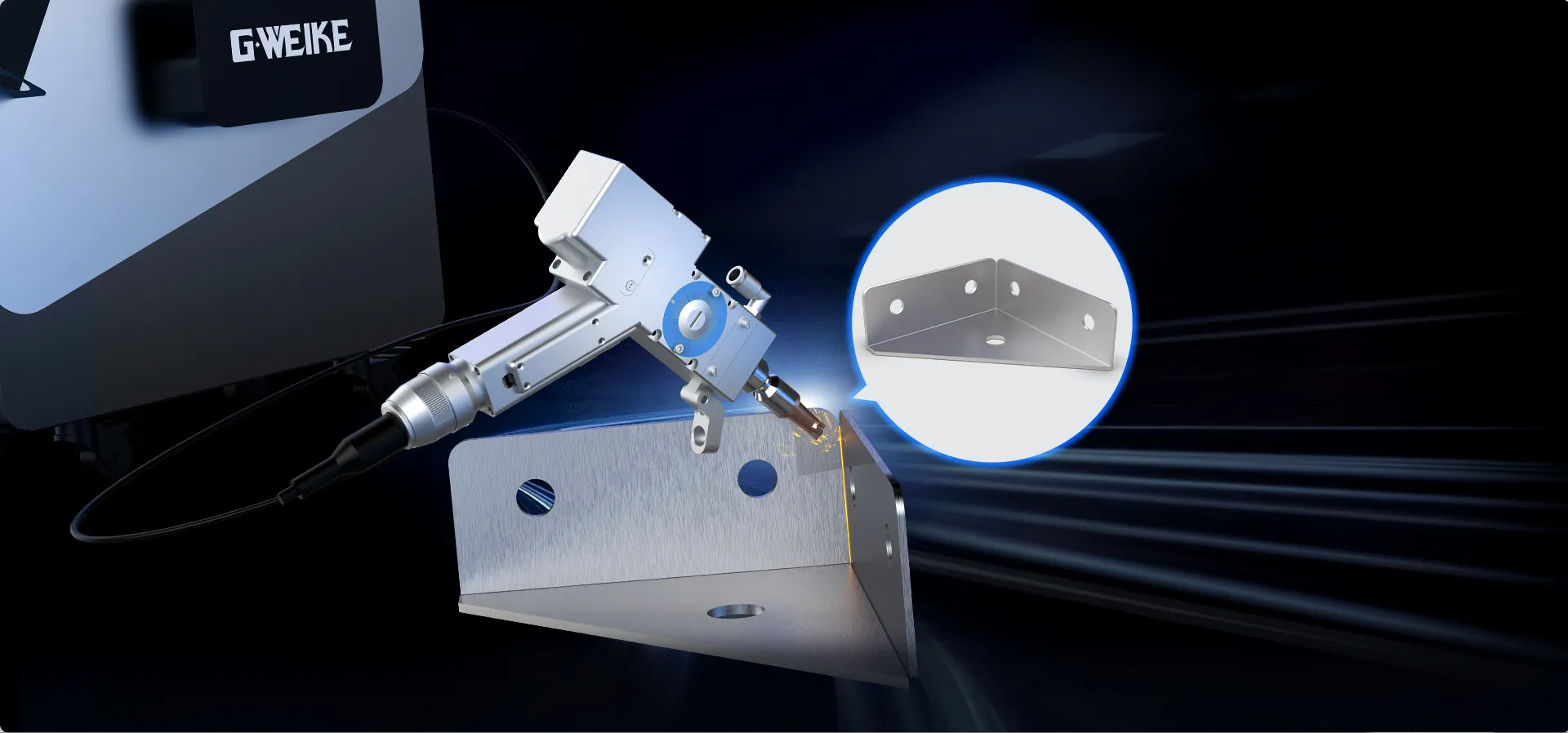

Laser Welding

Laser Cleaning

Handheld Cutting

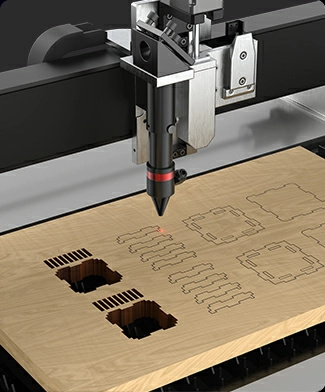

CO2 Laser Cutting

CO2 Laser Engraving

|

|

When encountering obstacles, the path can be automatically adjusted to avoid collisions, thereby reducing production interruptions caused by manual intervention, improving production efficiency and ensuring production safety.

Use efficient algorithms (such as automatic nesting, common edge cutting, and leftover material splicing) to maximize sheet material utilization, especially for special-shaped parts, which can save 15%~30% of raw materials.

Traditional independent cutting requires a reserved cutting margin (usually 0.2~0.5mm/edge), while common edge cutting eliminates redundant intervals by sharing a common cutting line, increasing material utilization by 10%~25% Shared edges only require one cut to separate adjacent parts, reducing the cutting stroke by 30%~50% compared to traditional methods

When cutting complex contours, by reserving micron-level tiny connection points (micro-connection points), the overall structure of the material is kept stable to avoid deformation or displacement of thin plates (such as 0.1~1mm) due to stress release during the cutting process.

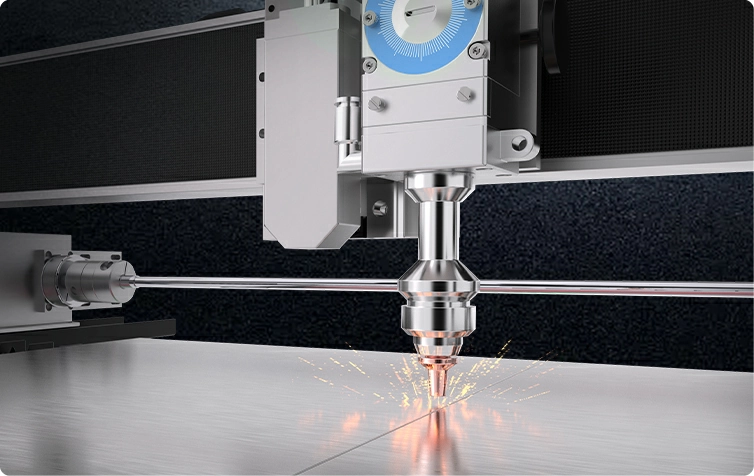

No-stop cutting, saving idle time, single positioning can complete the whole board cutting, greatly shortening the delivery cycle. The cutting head does not need to return to the origin after each processing, and can quickly jump and position on the board to achieve continuous cutting.

Laser Welder 1200W

Laser Welder 800W

Fiber Laser

Fiber Laser

1200W

800W

Welding / Cutting / Rust Removal & Cleaning

Welding / Cutting / Rust Removal & Cleaning

Continuous / Spot / Pulse Welding

Continuous / Spot / Pulse Welding

0.0078 - 0.197 in (0.2 - 5 mm)

0.0078 - 0.157 in (0.2 - 4 mm)

1080 ± 10 nm

1080 ± 10 nm

Nitrogen or Oxygen

Nitrogen or Oxygen

Air-cooling

Air-cooling

Class 4

Class 4

14 °F - 104 ℉ (-10 ℃ - 40 °C)

14 °F - 104 ℉ (-10 ℃ - 40 °C)

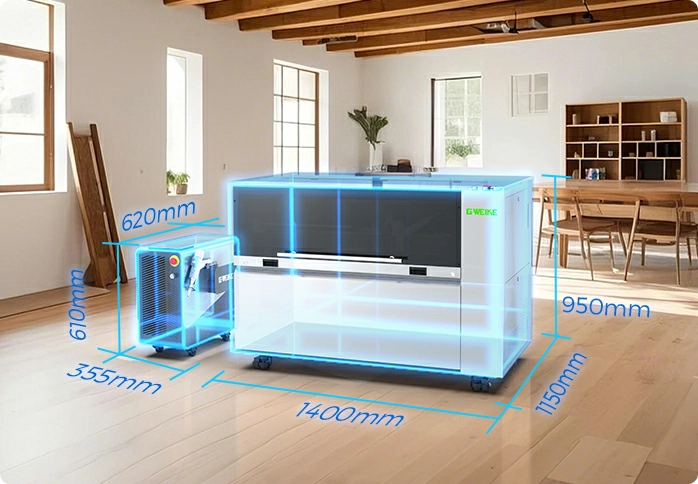

25.6 × 14 × 24.02in (620 × 355 × 610mm)

25.6 × 14 × 24.02in (620 × 355 × 610mm)

35kg

35kg

10m

10m

M2

M2 PRO

M2 MAX

M2 ULTRA

Fiber Laser

Fiber Laser

Fiber Laser

Fiber Laser

800W

1200W

800W

1200W

Welding / Cutting / Rust Removal & Cleaning/

CNC metal cutting

Welding / Cutting / Rust Removal & Cleaning/

CNC metal cutting

Welding / Cutting / Rust Removal & Cleaning/

CNC metal cutting

Welding / Cutting / Rust Removal & Cleaning/

CNC metal cutting

0.0078 – 0.157 in (0.2 – 4 mm)

0.0078 – 0.197 in (0.2 – 5 mm)

0.0078 – 0.157 in (0.2 – 4 mm)

0.0078 – 0.197 in (0.2 – 5 mm)

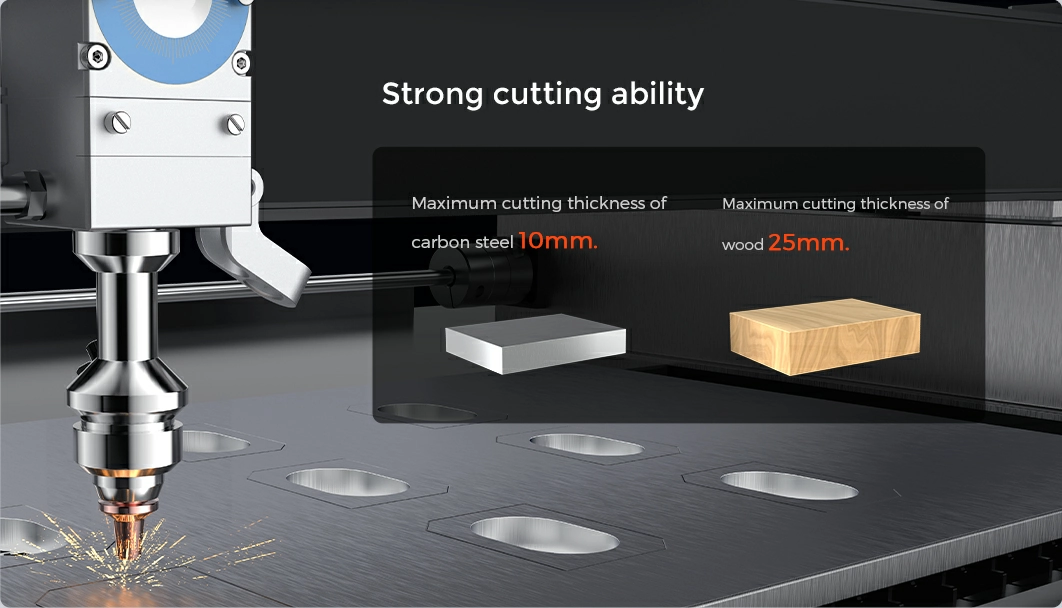

Up to 0.31 in (8 mm) with 800W fiber

Up to 0.39 in (10 mm) with 1200W fiber

Up to 0.31 in (8 mm) with 800W fiber

Up to 0.39 in (10 mm) with 1200W fiber

24.4 × 24.4 in (620 × 620 mm)

24.4 × 24.4 in (620 × 620 mm)

54.3 × 36.2 in (1380 × 920 mm)

54.3 × 36.2 in (1380 × 920 mm)

800 mm/s

800 mm/s

800 mm/s

800 mm/s

±0.03 mm

±0.03 mm

±0.03 mm

±0.03 mm

X: 48 m/min (800 mm/s)

Y: 30 m/min (500 mm/s)

X: 48 m/min (800 mm/s)

Y: 30 m/min (500 mm/s)

X: 48 m/min (800 mm/s)

Y: 30 m/min (500 mm/s)

X: 48 m/min (800 mm/s)

Y: 30 m/min (500 mm/s)

760 mm

760 mm

1450 mm

1450 mm

620 mm

620 mm

960 mm

960 mm

50 mm

50 mm

60 mm

60 mm

Class 4

Class 4

Class 4

Class 4

100 – 240V AC, 50/60 Hz

100 – 240V AC, 50/60 Hz

100 – 240V AC, 50/60 Hz

100 – 240V AC, 50/60 Hz

32 °F – 104 °F (0 °C – 40 °C)

32 °F – 104 °F (0 °C – 40 °C)

32 °F – 104 °F (0 °C – 40 °C)

32 °F – 104 °F (0 °C – 40 °C)

1080 ± 10 nm

1080 ± 10 nm

1080 ± 10 nm

1080 ± 10 nm

Nitrogen / Argon / Oxygen

Nitrogen / Argon / Oxygen

Nitrogen / Argon / Oxygen

Nitrogen / Argon / Oxygen

Air Cooling

Air Cooling

Air Cooling

Air Cooling

25.6 × 14 × 24.02 in (620 × 355 × 610 mm) +

55,1× 45.2 ×37.4 in (1400 × 1150 × 950mm)

25.6 × 14 × 24.02 in (620 × 355 × 610 mm) +

55,1× 45.2 ×37.4 in (1400 × 1150 × 950mm)

25.6 × 14 × 24.02 in (620 × 355 × 610 mm) +

86 × 71 × 43.3 in (2185mm × 1780mm × 1100mm)

25.6 × 14 × 24.02 in (620 × 355 × 610 mm) +

86 × 71 × 43.3 in (2185mm × 1780mm × 1100mm)

250 kg

250 kg

560 kg

560 kg

10m

10m

10m

10m

M3

M3 PRO

M3 MAX

M3 ULTRA

Fiber Laser

Fiber Laser

Fiber Laser

Fiber Laser

800W Fiber laser + 80W CO2 laser

1200W Fiber laser + 80W CO2 laser

800W Fiber laser + 130W CO2 laser

1200W Fiber laser + 130W CO2 laser

Welding / Cutting / Rust Removal & Cleaning/

CNC metal cutting / CO2 Cutting / CO2 Engraving

Welding / Cutting / Rust Removal & Cleaning/

CNC metal cutting / CO2 Cutting / CO2 Engraving

Welding / Cutting / Rust Removal & Cleaning/

CNC metal cutting / CO2 Cutting / CO2 Engraving

Welding / Cutting / Rust Removal & Cleaning/

CNC metal cutting / CO2 Cutting / CO2 Engraving

0.0078 – 0.157 in (0.2 – 4 mm)

0.0078 – 0.197 in (0.2 – 5 mm)

0.0078 – 0.157 in (0.2 – 4 mm)

0.0078 – 0.197 in (0.2 – 5 mm)

Up to 0.31 in (8mm) with 800W fiber laser Source /

Up to 0.79 in (20mm) with 80W CO2 laser tube

Up to 0.39 in (10mm) with 1200W fiber laser Source /

Up to 0.79 in (20mm) with 80W CO2 laser tube

Up to 0.31 in (8mm) with 800W fiber laser Source /

Up to 1 in (25mm) with 130W CO2 laser tube

Up to 0.39 in (10mm) with 1200W fiber laser Source /

Up to 1 in (25mm) with 130W CO2 laser tube

24.4 × 24.4 in (620 × 620 mm)

24.4 × 24.4 in (620 × 620 mm)

54.3 × 36.2 in (1380 × 920 mm)

54.3 × 36.2 in (1380 × 920 mm)

800 mm/s

800 mm/s

800 mm/s

800 mm/s

±0.03 mm

±0.03 mm

±0.03 mm

±0.03 mm

X: 48 m/min (800 mm/s)

Y: 30 m/min (500 mm/s)

X: 48 m/min (800 mm/s)

Y: 30 m/min (500 mm/s)

X: 48 m/min (800 mm/s)

Y: 30 m/min (500 mm/s)

X: 48 m/min (800 mm/s)

Y: 30 m/min (500 mm/s)

760 mm

760 mm

1450 mm

1450 mm

620 mm

620 mm

960 mm

960 mm

50 mm

50 mm

60 mm

60 mm

Class 4

Class 4

Class 4

Class 4

100 – 240V AC, 50/60 Hz

100 – 240V AC, 50/60 Hz

100 – 240V AC, 50/60 Hz

100 – 240V AC, 50/60 Hz

32 °F – 104 °F (0 °C – 40 °C)

32 °F – 104 °F (0 °C – 40 °C)

32 °F – 104 °F (0 °C – 40 °C)

32 °F – 104 °F (0 °C – 40 °C)

1080 ± 10 nm

1080 ± 10 nm

1080 ± 10 nm

1080 ± 10 nm

Nitrogen / Argon / Oxygen

Nitrogen / Argon / Oxygen

Nitrogen / Argon / Oxygen

Nitrogen / Argon / Oxygen

Air Cooling + Water Cooling

Air Cooling + Water Cooling

Air Cooling + Water Cooling

Air Cooling + Water Cooling

25.6 × 14 × 24.02 in (620 × 355 × 610 mm) +

49.2 × 38.5 × 37.4 in (1250mm × 980mm × 950mm)

25.6 × 14 × 24.02 in (620 × 355 × 610 mm) +

49.2 × 38.5 × 37.4 in (1250mm × 980mm × 950mm)

25.6 × 14 × 24.02 in (620 × 355 × 610 mm) +

86 × 71 × 43.3 in (2185mm × 1780mm × 1100mm)

25.6 × 14 × 24.02 in (620 × 355 × 610 mm) +

86 × 71 × 43.3 in (2185 × 1780 × 1100mm)

310 kg

310 kg

630 kg

630 kg

10m

10m

10m

10m

Traditional tools such as saws and carving knives are difficult to operate with low precision. In contrast, this all-in-one machine offers high-precision laser cutting (±0.01mm) and engraving capabilities, supporting intricate graphic designs and reducing the need for manual polishing.

The CO2 laser engraving function enables detailed engraving on materials such as wood, leather, and glass, while the metal cutting and welding functions are ideal for jewelry and souvenir customization. The integrated operation interface and intelligent control system make the processing easier for users.

Fiber laser welding provides high-quality weld seams, enhancing welding quality. The efficient cleaning function removes oil and oxide layers from metal surfaces, making it suitable for metal repair and processing. Laser cutting is fast and precise, perfect for customized processing.

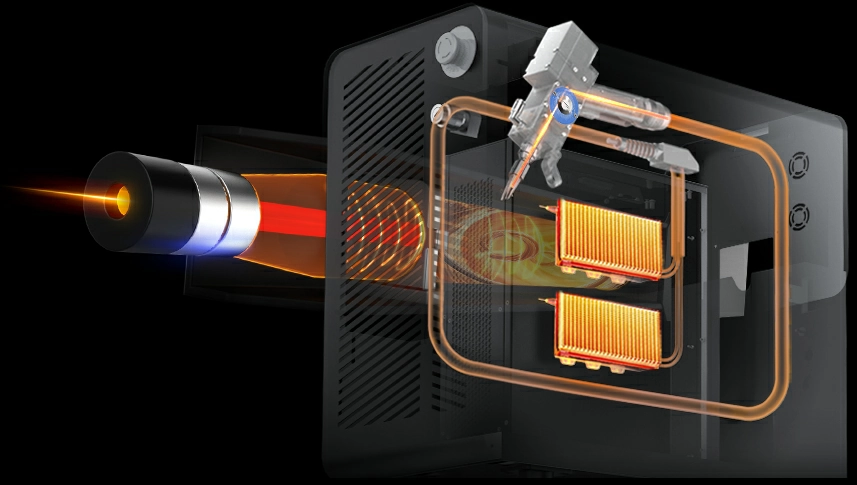

Traditional equipment requires multiple machines to complete cutting, welding, and other processes. In contrast, MultiLase Pro integrates multiple functions, saving space and costs. Additionally, the dual laser technology of fiber and CO2 lasers makes it compatible with both metal and non-metal materials.

Traditional equipment has a high operational threshold and requires professional guidance. In contrast, MultiLase Pro is equipped with an automated numerical control system (CNC) and a user-friendly interface, allowing beginners to quickly get started without chemical pollution risks (Safe for campus use).

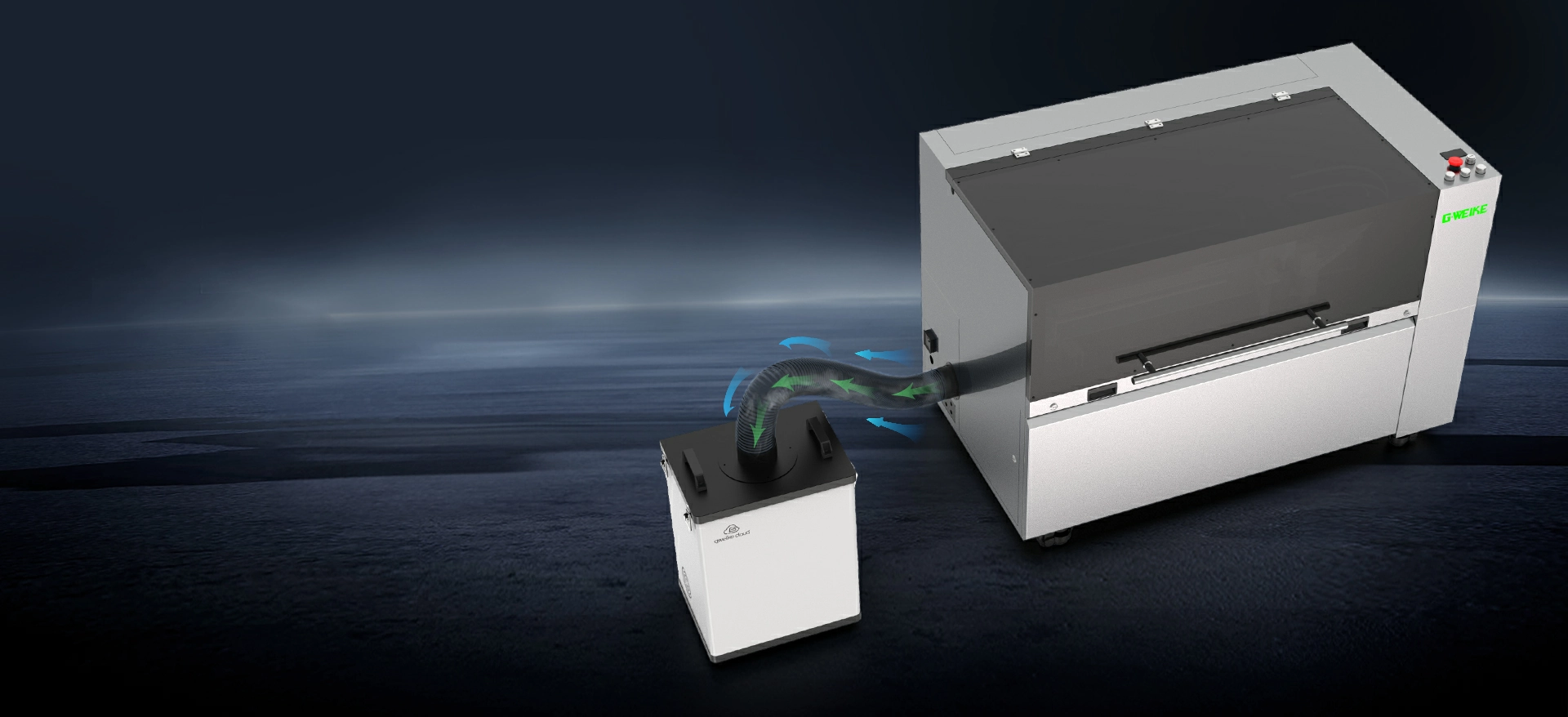

Traditional equipment (such as oxygen-fuel cutting) generates exhaust pollution. In costrast, fiber lasers have low energy consumption (30-50% less electricity than CO₂ lasers), and laser cleaning produces no wastewater, complying with environmental regulations (EPA standards).

20-year Experience

Production Base

Annual Capacity

Global Sales