9 Types of Sheet Metal Laser Cutting Machines

In recent years, laser cutting machines, as a new and efficient cutting tool, have occupied more of the market share of traditional metal cutting machines. With the technological advancement of the industry and the increasing demands of customers, manufacturers have developed many types of laser cutting machines such as laser plate cutting machines, laser pipe cutting machines, cutting robots, etc. to meet different customer needs. There are many types and functions of these laser cutting machines. For beginners who want to buy a laser cutting machine to improve productivity, choosing a suitable laser cutting machine requires a lot of effort and time. As a professional laser equipment manufacturer and service provider, we have listed the characteristics and advantages of several common metal sheet laser cutting machines on the market to help you find a suitable laser cutter in a short time.

What is metal sheet a laser cutting machine?

Before choosing a metal sheet laser cutting machine, we should know its basic structure and work process of the machine. As that knowledge will allow us to better understand the differences between various types of laser metal cutting machines.

Generally speaking, a laser cutting machine mainly consists of the laser source, laser head, machine bed, beam, and control system.

Laser source

The laser source is the core component of the metal sheet laser cutting machine. Laser sources are mainly divided into CO2 laser tubes and fiber laser sources. The working principle of the CO2 laser tube is to use the transition between the vibration and rotational energy levels of carbon dioxide molecules to generate laser beams. Fiber laser sources generally use optical pumping. The pump light is coupled to the fiber. Photons at the pump wavelength are absorbed by the medium, causing particle number inversion. Finally, stimulated radiation is generated in the fiber medium to output laser light. Nowadays, CO2 laser tube on the market is generally used to cut non-metallic and thin metal plates. Fiber laser sources are mainly used to cut various types of metal thin plates, medium and thick plates. The beam emitted by the fiber optic device is more stable than carbon dioxide, and the laser beam quality is also better.

Laser cutting head

The laser cutting head is used to process the laser beams emitted by the laser source. The lens inside the laser cutting head makes the laser beam more focused, which is more conducive to cutting.

Beam

The beam is used to fix the laser cutting head, both ends of the beam and the position where the laser head is fixed are equipped with motors. The beam is driven by the motors to move the laser head on the platform, allowing the machine to complete the cutting of various complex graphics.

Machine body

The machine body is the place where cutting materials, beam, and other accessories are placed. The size of the machine determines the size of the material that can be placed at one time.

Control System

Control system is used to input graphics that need to be processed and control the operation of the metal sheet laser cutting machine.

Working process:

After the laser cutting machine is powered on, the laser source first emits beams, then the laser cutting head processes and emits the laser beams which directly act on the metal plate to penetrate the plate through high temperature, and finally the beam takes the laser cutting head to different positions of the metal plate to complete the graphic cutting.

Advantages of metal sheet laser cutting machine:

Fast cutting speed

According to research, we conclude that the cutting speed of laser cutting machines is faster than most plate-cutting machines on the market. As the beam emitted by the laser has a large amount of energy, it can quickly penetrate the surface of the materials.

High Precision

The smallest spot of the laser cutting machine can reach 0.01mm. The cutting accuracy of CO2 laser cutting machines is generally within ±0.05mm, and the accuracy of fiber laser cutting machines is within ±0.03mm, which is suitable for the production of precision workpieces.

Few wearing parts

The service life of the laser source is very long. For the CO2 laser tube, the service life is about 10,000 hours, while the service life of the fiber laser can reach about 100,000 hours. Besides, there is no need to use other media to process materials, which can save a lot of machine maintenance costs and maintenance time.

Intelligent

The laser cutting machines are equipped with intelligent operating systems. After the user inputs the graphics, the laser cutting machine can not only control the machine to complete cutting but also calculate the most appropriate path based on the graphics to be processed, which saves time and cutting materials.

Suitable for batch processing

Due to its fast cutting speed, stable performance, and intelligent operating system, the laser cutting machine can be used for batch processing. In addition, the laser cutting machine can be equipped with CNC accessories such as the automatic loading and unloading machine, coiling machine, the exchange platform, which greatly improve the efficiency of the laser plate cutting machine and saves more labor costs.

Types of sheet metal laser cutting machines

After understanding the main components and working principles of metal sheet laser cutting machines, let’s get to the point of taking a look at some of the common laser metal cutting machines on the market and their characteristics.

1.CO2 sheet metal laser cutting machine

A CO2 sheet metal laser cutting machine is a laser cutter that uses a carbon dioxide laser tube as the laser source. This kind of cutting machine has relatively low power and is generally used to cut non-metallic materials and thin metal plates. The price is cheap but the cutting effect and efficiency are worse than those of fiber laser cutting machines.

2. Hybrid sheet metal laser cutting machine

The hybrid laser cutting machine is a laser cutting machine equipped with two lasers (CO2 laser tube & fiber laser source) and two laser cutting heads. The CO2 laser is used to cut non-metallic materials, and the fiber laser source is used to cut non-metallic materials. The hybrid laser cutting machine can save customers space and purchasing costs and is mainly used for cutting thin plates. The following LF1325LC is a CO2 &fiber laser cutting machine independently developed by GWEIKE.

3. Single platform metal sheet fiber laser plate cutting machine

The single-platform metal sheet fiber laser cutting machine is a common metal laser cutting machine on the market. It is generally equipped with one fiber laser source and one working platform. Work platform size and laser source can be customized according to processing demands. The single-platform sheet metal fiber laser cutting machine is moderately priced and can meet most cutting needs. It is suitable for customers with limited budget and moderate processing volume.

The picture below is GWEIKE's classic single platform sheet metal fiber laser cutting machine LF3015LN.

4. Dual-platform sheet metal fiber laser cutting machine

Compared with the single-platform fiber laser cutting machine, the dual-platform fiber laser cutting machine adds an exchange platform. Users can replace the materials on another exchange platform while the laser cutting machine is cutting one plate. This greatly saves the time of changing materials and improves the cutting efficiency. The price of a dual-platform laser cutting machine is higher than that of a single-platform machine, and a dual-platform fiber laser cutter is suitable for customers who need to process products in batches.

The picture below is GWEIKE’S dual-platform sheet metal fiber laser cutting machine LF3015GC.

5. Full cover sheet metal fiber laser cutting machine

The full-cover fiber laser cutting machine adds a protective cover based on a single-platform cutting machine or a double-platform fiber laser cutting machine and glass to prevent laser radiation. Since the laser cutting machine will produce smoke when cutting, adding a protective cover can avoid the spread of smoke and protect the environment around the laser cutting machine. The radiation-proof glass on the protective cover can better protect the operator's eyes from being harmed by the light radiation emitted by the laser cutting head. It is more suitable for users with high requirements for the processing environment.

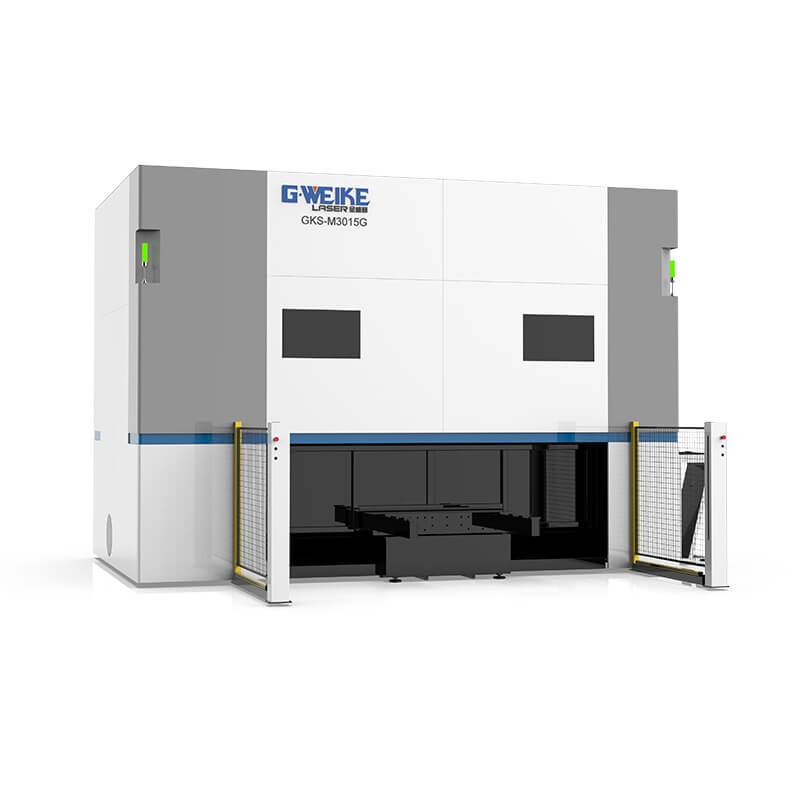

The picture below is GWEIKE’S full cover sheet metal fiber laser cutting machine LF3015GA.

6. Tube and sheet metal fiber laser cutting machine

The tube and sheet metal fiber laser cutting machine extends the beam and rotary based on the general plate cutting machine. It can be used to cut both plates and metal pipes in one machine. It greatly reduces the customer's procurement cost and also reduces the machine's floor space. It is suitable for customers who have both plate processing and pipe processing demands.

The picture below GWEIKE LF3015CNR tube and sheet metal fiber laser cutting machine.

7. Bevel sheet metal fiber laser cutting machine

The main difference between bevel sheet metal fiber laser cutting machines and general fiber laser cutting machines lies in the laser cutting head. The general fiber laser cutting head cannot tilt and can only move left and right and up and down on the beam, while the bevel cutting head can tilt from 0 to 45 degrees and can produce some workpieces with a certain slope. This greatly expands the application range of laser cutting machines and also reduces many workpiece processing processes and costs for customers who need to produce special-shaped parts.

The picture below is a sample cut by GWEIKE GKS12025SLG-30KW.

8.Automatic loading and unloading sheet metal fiber laser cutting machine

Generally, a metal sheet fiber laser cutting machine and an automatic loading and unloading device constitute an automatic loading and unloading fiber laser cutting machine. This kind of fiber laser cutting machine is used for batch processing. The automatic loading and unloading device replaces manual labor. It enables uninterrupted work throughout the day, which not only saves labor costs but also increases the production efficiency of the fiber laser cutting machine.

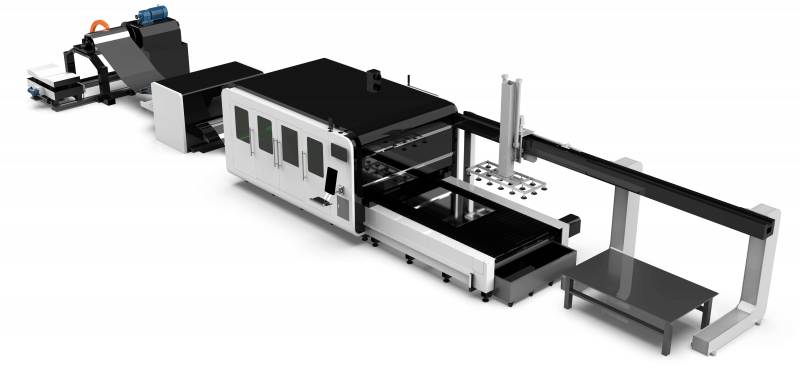

The picture below shows an automatic loading and unloading sheet metal fiber laser cutting machine LF3015MB produced by GWEIKE

9.3D sheet metal fiber laser cutting machine

The 3D fiber laser cutting machine is a special type of metal cutting machine designed and developed for cutting irregular metal plates. This machine eliminates the beam as an accessory, allowing the laser cutting head to rotate 360 degrees, thereby achieving incomplete cuts. Cut on a flat surface. The picture below shows the latest 3D five-axis fiber laser cutting machine developed by GWEIKE, which has ultra-high precision and flexibility.

The above is a brief introduction to several common laser cutting machines. If you are interested in one of the cutting machines and want to know more information, you can check it on our website or contact us directly. It's our pleasure to provide you with the best laser cutting machine according to your needs.